Self-Spinning Grains Prove Granular Theory

Grains falling in an avalanche or swirling around in a sand storm behave like molecules in a gas, so researchers have developed a gas-like theory for such systems. But one key prediction regarding the particle velocities has yet to be verified unambiguously. A new experiment solidly confirms the prediction using specially designed, 3D-printed grains that spin around when placed on a vibrating table. With this confirmation, researchers can have confidence that gas-based models are accurate. These models apply to granular flows, as well as the grain-filled rings around Saturn and other planets.

Based on the similarity between dilute granular materials and molecular gases, researchers have developed a model of grains that allows systems such as a sandstorm to be assigned a “temperature” and to be described within textbook concepts of thermodynamics. This model was developed from the centuries-old kinetic theory of gases, which assumes that the molecules engage in brief, random collisions that allow them to continually exchange energy (see 10 October 2000 Focus story). Within this framework, theorists have predicted that the velocity distribution of grains (curve showing the probability for each possible speed) should resemble that of a molecular gas, but not exactly .

The two systems are expected to diverge at the highest speeds; the granular gas should have more high-speed particles than the conventional gas has. The reason is that grains—unlike molecules—lose kinetic energy in collisions. This loss of energy shifts the majority of grains to lower velocities, but some grains luck out and avoid collisions, retaining their high initial velocities. “The high-velocity particles are forgotten by thermalization,” says Thorsten Pöschel from Friedrich Alexander University (FAU) in Erlangen, Germany.

Previous experimenters have tried to confirm this theoretical picture of granular gases. The typical setup is a vibrating table with a rough surface that gives random kicks to the grains, which could be tiny metal or plastic beads. One of the problems, however, has been that the kicks are not entirely random, and the particles clump up, rather than remaining uniformly spread out like a true gas. A possible solution—first proposed over a decade ago—is to inject energy into the rotational motion of the grains [1]. This rotational energy would be subsequently transferred to translational motion when two grains collide with each other.

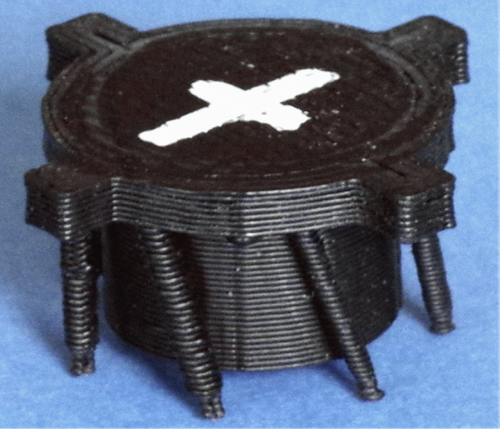

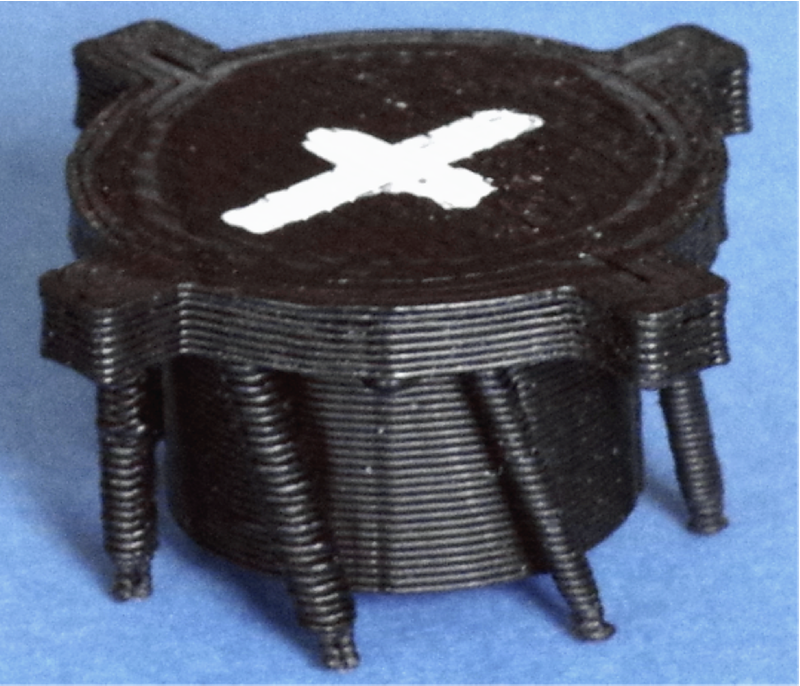

Building on previous work [2], Pöschel and FAU colleague Christian Scholz have used 3D printing technology to fabricate grains that rotate when subjected to vibration. The team’s “vibrots” are each 15 mm across and look like plastic beetles with seven slanted legs. The tilt of those legs causes a random rotation of the vibrot each time it bounces on a surface, as the researchers verified with a single vibrot on their vibrating table. At a vibration frequency of 50 Hz, the vibrot rotated clockwise at various rates between 0 and 6 revolutions per second.

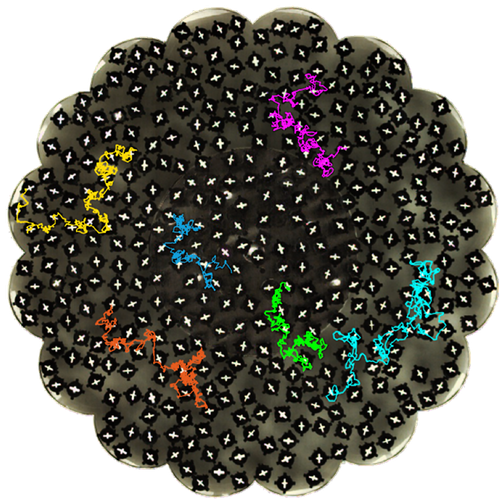

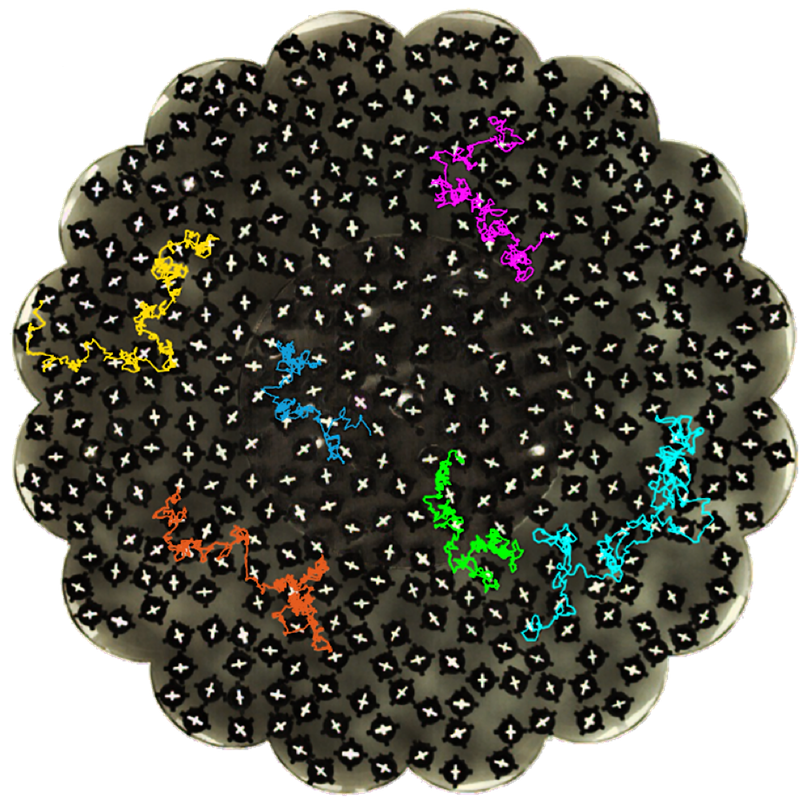

To observe vibrot gas behavior, the team placed several hundred vibrots together on their vibrating table. Whenever two grains collided, some of the rotational energy of one could bump the other in a horizontal direction. To check that these translational kicks were random, the team measured the spatial distribution of grains on the surface and found no clumping except for a slight amount of inhomogeneity near the outer boundary wall of the table.

The researchers also measured the velocity distribution, finding that the low velocity behavior resembled a molecular gas with an average velocity of 20 mm/s. But there were more grains at high velocity, above 60 mm/s, than would be expected for the molecular case. The shape of this overpopulated tail of the distribution agreed with the prediction from kinetic theory. This confirmation lends support to the use of kinetic theory in other situations, such as cosmic dust and rapid granular flows.

“I loved this ingenious idea of 3D printing vibrots and obtaining a measurable equilibrium between rotation and translation,” says granular physics expert Hans Herrmann from the Swiss Federal Institute of Technology (ETH) in Zurich. “It is very original, and indeed one can argue that this experiment does not have the bias of previous experiments.” Diego Maza, another physicist in the field, from the University of Navarra in Spain, agrees. “I like this paper so much,” he says, because it is the first experimental study to guarantee a separation between the input energy and the kinetic motion of the grains.

This research is published in Physical Review Letters.

–Michael Schirber

Michael Schirber is a Corresponding Editor for Physics Magazine based in Lyon, France.

References

- R. Cafiero, S. Luding, and H. J. Herrmann, “Rotationally Driven Gas of Inelastic Rough Spheres,” Europhys. Lett. 60, 854 (2002).

- E. Altshuler, J. M. Pastor, A. Garcimartín, I. Zuriguel, and D. Maza, “Vibrot, a Simple Device for the Conversion of Vibration into Rotation Mediated by Friction: Preliminary Evaluation,” PLoS ONE 8, e67838 (2013).