Programmable Material Inspired by Muscle

Skeletal muscle, the muscle tissue that vertebrates can actively control, has a unique microscopic structure that allows it to generate force and regain lost tension. If material designers could mimic this structure, they might be able to develop robust and adaptable components for robots. Now, Narayanan Kidambi of the University of Michigan, Ann Arbor, and colleagues have created a modular material that adopts multiple geometric arrangements. By switching between arrangements, the material can generate force and store mechanical energy.

Muscle fibers contain parallel filaments of proteins that are linked by “cross bridges.” By changing their shape and orientation, these cross bridges can force the filaments to slide relative each other, resulting in muscle contraction.

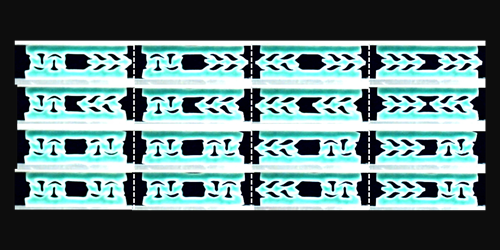

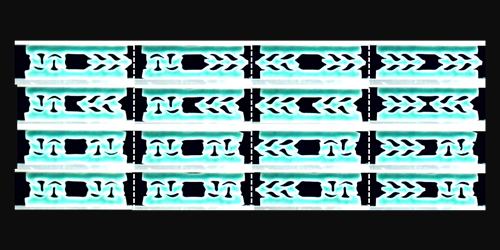

Inspired by this cross-bridge structure, the team designed a square of silicone rubber, 15 mm on a side, with four holes embedded within. When this module is compressed, the circular holes deform, adopting one of several stable configurations. For example, the scrunched holes might all lean to one side, or some might flatten horizontally while adjacent holes flatten vertically. Each configuration can store a different quantity of elastic energy, and a switch between two configurations generates a shear force perpendicular to the compression direction.

The material’s true power comes about when multiple modules are lined up. By cycling through the different configurations for each module, the ensemble can deliver a shear force with a range of magnitudes and directions. For now, the team must manually nudge the compressed material into specific configurations with a pair of tweezers. One of their next goals is to replace the tweezers with actuators, which would allow the shapes to be controlled remotely. They hope that such a modular system could become a novel building block for soft robotics designs (see related 24 October 2014 Focus story).

This research is published in Physical Review E.

–Christopher Crockett

Christopher Crockett is a freelance writer based in Arlington, Virginia.