Wonder Material Grows on Trees

To shape the future, next-generation materials need not be as exotic as topological insulators and metamaterials. Researchers are investigating the potential of nanocellulose—a nanostructured form of cellulose that can be obtained from the humble wood chip—for applications ranging from microfluidic devices to rechargeable batteries. A team led by Liangbing Hu at the University of Maryland in College Park reported at the 2019 Fall Meeting of the Material Research Society in Boston that a material that combines nanocellulose with graphite has mechanical properties that surpass those of steels and of other established structural materials. The recyclable composite could offer an environmentally friendly alternative for building lightweight vehicles, aircraft, and body armor.

Hu presented an overview of his quest for replacing traditional materials with sustainable ones based on wood nanocellulose. The cellulose fibers that make up nanocellulose have diameters of between 5 and 20 nm and lengths of several micrometers. They are typically prepared from wood pulp using mechanical methods that rip the pulp’s wood fibers into nanoscale whiskers.

“Wood and materials derived from [wood] have a lot to offer,” Hu says, noting that wood-based materials are recyclable, biocompatible, and biodegradable. “These are fantastic properties, but to make these materials successful, we need to show that their performance is superior to that of traditional materials,” he adds.

Using nanocellulose, Hu’s team has recently demonstrated a transparent wood that could stand in for glass and a high-strength nanopaper that could replace plastic. In the new work, they went after mimicking the structural properties of steel.

Structural materials owe their strength to the presence of strong, primary chemical bonds between their atoms: metallic bonds in metals and metal alloys, carbon-carbon covalent bonds in carbon fibers, and ionic bonds in ceramics. The strength of these bonds, however, is both a blessing and a curse. To manipulate, manufacture, and recycle these materials, these bonds must be broken and reformed, which requires high temperatures and consumes large amounts of energy, leading to a substantial cost and a hefty environmental footprint.

The material design strategy of Hu and his colleagues leverages secondary chemical bonds, such as the hydrogen bonds that are abundant in organic materials like nanocellulose. While the energy needed to make or break an individual hydrogen bond is much smaller than that of a primary chemical bond, networks of these bonds can make a material extremely strong, something the team knew from their previous work on cellulose nanopaper. Their nanopaper is orders of magnitude stronger and tougher than regular paper, thanks to the copious number of secondary hydrogen bonds that form between the paper’s cellulose nanofibers, and thanks to the ease and speed with which these bonds reform when broken.

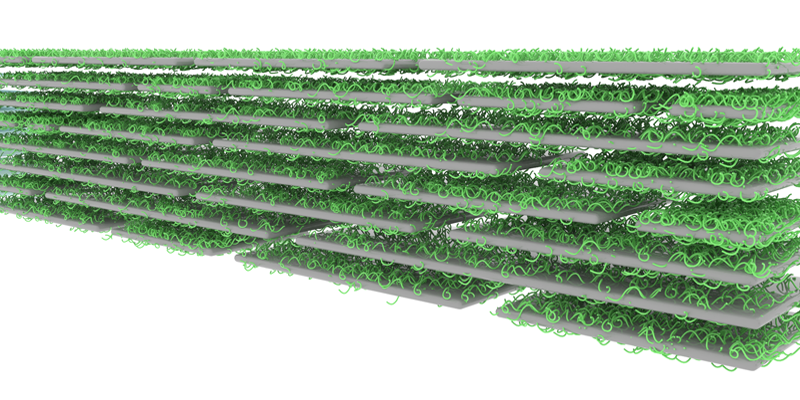

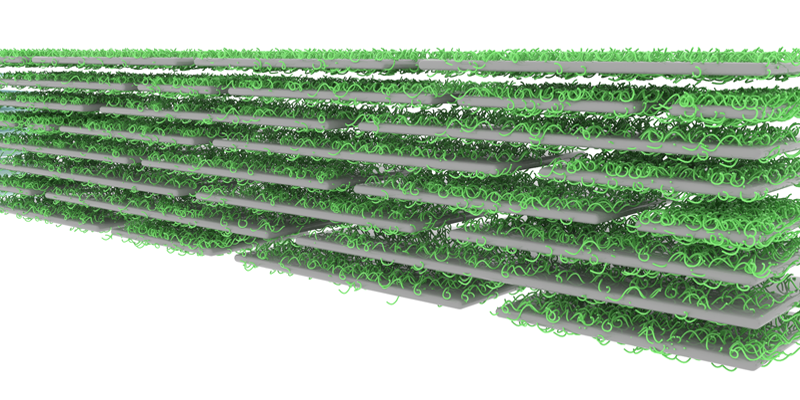

For the steel-like material, the team harnessed these bonds to “stick” the cellulose to graphite, which is hard but too brittle to be used in load-bearing structures. To fabricate a graphite-nanocellulose composite, they prepared a highly concentrated slurry of water, graphite flakes, and nanocellulose at room temperature. They then cast-printed this mixture into meter-large, 20-𝜇m-thick layers. The layers were flexible—they could be bent to a radius of 2 mm without breaking—and multiple layers could be hot pressed into thicker sheets.

Mechanical measurements show that the material is exceptionally strong. The printed sheets are stronger than stainless steel and 6 times as light. The material’s specific strength (defined as the strength divided by the material’s density) is higher than that of materials used in structural applications, like steels, aluminum alloys, and titanium alloys.

The researchers characterized the composite to reveal the microscopic structure behind its mechanical properties, using a combination of atomic force microscopy, transmission electron microscopy, and molecular dynamics simulations. Their analysis suggests that thousands of cellulose nanofibers attach to each of the graphite flakes—whose sizes are in the hundreds of micrometers range—through hydrogen bonding. The fibers also link different graphite flakes. “It’s like a brick wall, where the graphite flakes are the bricks, and the cellulose nanofibers are the mortar that glues the bricks together,” says Yubing Zhou, the postdoctoral fellow in Hu’s group who led the study.

Hu quotes several environmental advantages of the composite. Its fabrication process doesn’t involve the use of any harsh chemicals, and the composite can be easily recycled—a simple cutting and stirring process can turn the material back into the original slurry. “The material’s properties are exceptional. Now we just need to find cheaper ways to make it and scale up the production process,” says Hu.

–Matteo Rini

Matteo Rini is the Deputy Editor of Physics.