Handwritten LEDs Light Up the Page

Even in our digital age, ballpoint pens are an irreplaceable tool for writing down flashes of inspiration or signing legally binding documents. The ink flowing through these everyday objects has always been a passive absorber of light, but Junyi Zhao from Washington University in St. Louis and colleagues have now changed that [1]. The team has designed a ballpoint pen that writes with ink that produces light as a light emitting diode (LED).

LEDs are used in everything from TV screens to lightbulbs. They are often made using highly tunable semiconducting materials called halide perovskites. However, these devices have traditionally been time and energy intensive to fabricate, and they do not easily adhere to nonuniform substrates, such as fabric and plastic.

To address these issues, Zhao and colleagues turned to a fabrication approach that was both rapid and user friendly: the ballpoint pen. The idea grew out of earlier work by the same group in which they used an inkjet printer to create perovskite LEDs on nonrigid surfaces. Inkjet printers are common, but a ballpoint pen is a faster tool that can be easily picked up by both scientists and the general public, Zhao says. Beyond its novelty, the team also believes that this pen could have applications in designing flexible e-textiles, smart packaging, and wearable electronics that are highly customizable and fast to manufacture.

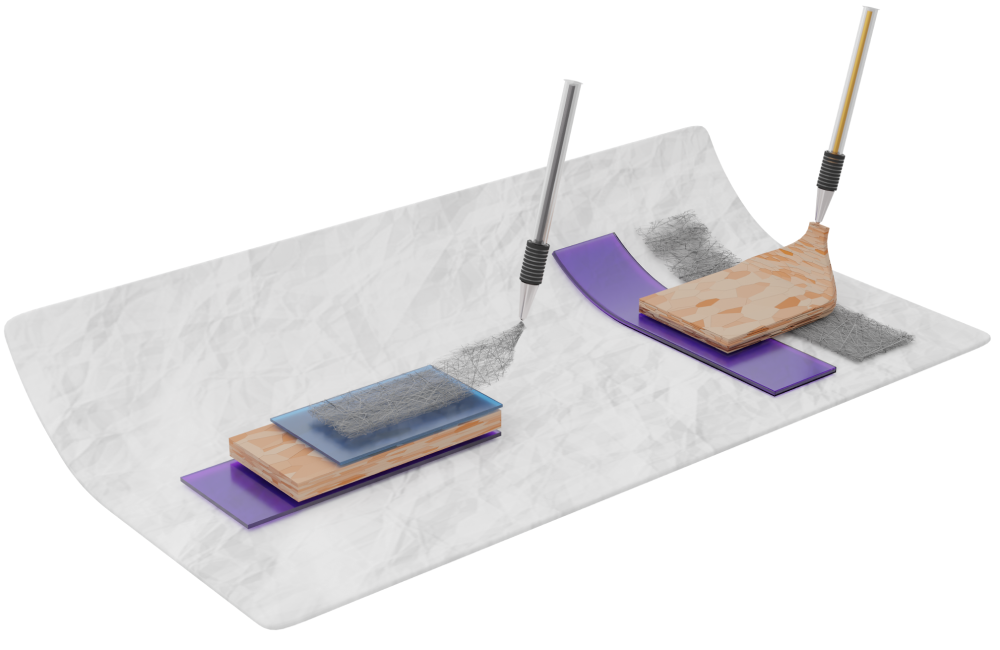

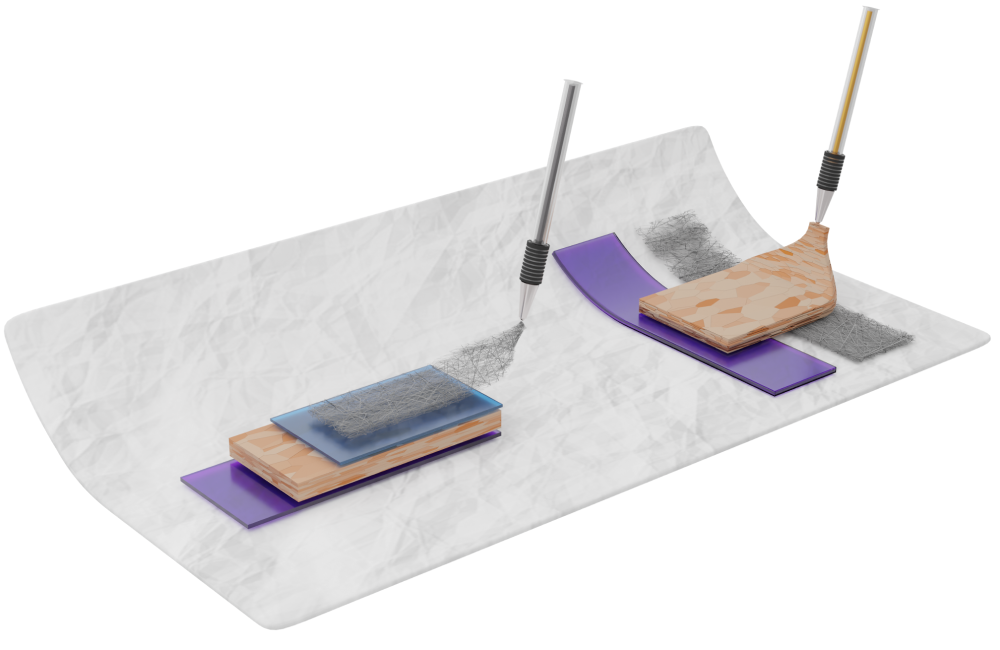

To make this possible, Zhao and colleagues created four different “inks” designed to be layered on top of each other using a set of pens. The first ink to be applied is a conductive polymer that seeps into the fabric or other substrate to help create a smooth surface for subsequent layers. The next ink is a perovskite material that has been diluted using a solvent. The third ink is another polymer that forms a buffer layer, and the last is a conducting ink that contains silver nanowires.

The researchers calibrated the ink viscosity and other properties so that they resembled those of traditional pen inks. “This deliberate alignment of ink properties facilitated a writing experience akin to [that] encountered in daily life,” Zhao says.

The research team applied these inks to everyday substrates—such as the inside of a glass vial, the surface of a rubber balloon, and the tip of a plastic glove. They connected the ink layers to a small battery and observed emissions at a variety of colors (red, green, and blue), depending on the exact perovskite used. The team measured the luminance (luminous intensity per area) of the LEDs and found maximum values around 15,000 candela per m2, which is several times higher than a typical cell phone screen.

Zhao and colleagues were able to fabricate these ink-based LEDs in a matter of minutes and found that the pens could apply the layers to nonflat surfaces better than inkjet printing and more evenly than roll printing. They also found that the LEDs withstood multiple rounds of bending, twisting, folding, and inflating across the different surfaces.

Sam Stranks, a physicist at the University of Cambridge, and Wei Liu, a materials scientist at the University of Chicago, both agree that this work will open exciting new doors into the research of flexible light-interacting electronics, such as photodetectors and solar cells. However, they also believe that future work will need to study the consistency and longevity of this application approach.

“It is still challenging to pen print every layer without damaging the underneath layers,” Liu says. “Further research could delve into optimizing the printing process to ensure uniform performance and long-term reliability.”

Likewise, Stranks says that the team will need to test whether the pens can operate without performance loss over extended periods of time. “The demonstrations in the paper are somewhat promising, but more validation would be needed to demonstrate many thousands of hours of operation,” he says.

Beyond encouraging new areas of research, Zhao says that the pen could become a part of popular science demonstrations. The researchers are looking into collaborations with educational toy companies in developing a product based on this technology that could introduce applied and fundamental physics concepts in elementary school classrooms, he says.

–Sarah Wells

Sarah Wells is an independent science journalist based outside of Washington, DC.

References

- J. Zhao et al., “Handwriting of perovskite optoelectronic devices on diverse substrates,” Nat. Photonics (2023).