The Optimal Angle for Cleaning with Bubbles

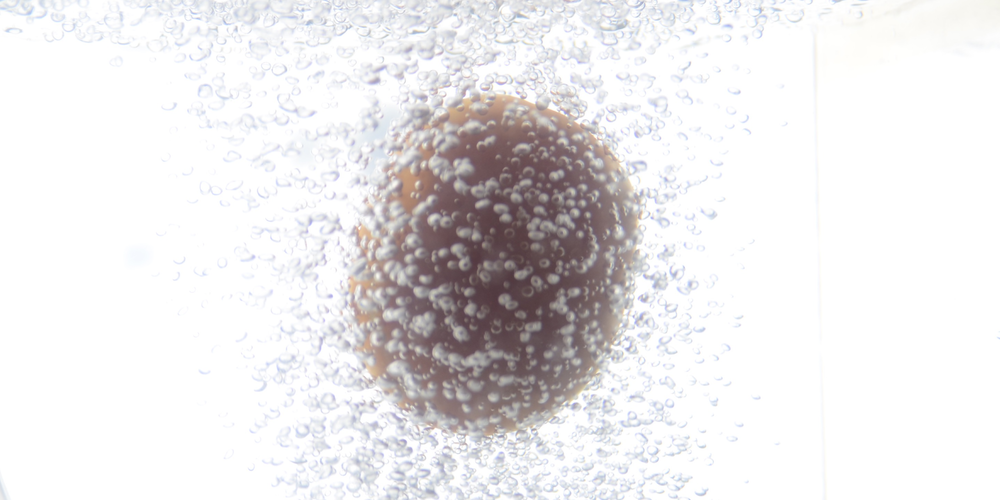

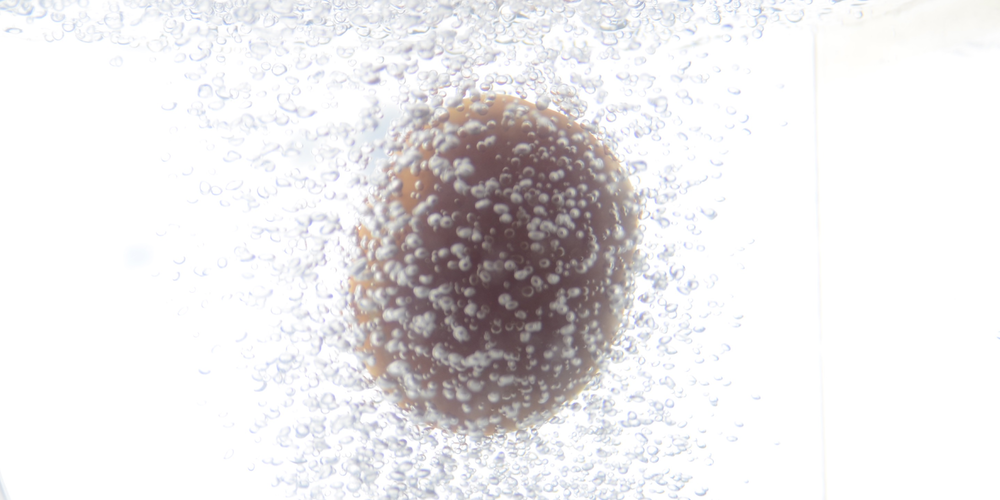

Researchers believe that washing vegetables and food-processing equipment with flowing liquids filled with air bubbles could be effective, but little is known about how to optimize the process. Now engineers, using experiments and simulations, have shown that bubbles exert an optimal cleaning effect if they strike a surface at an angle of about 22.5° [1]. The researchers hope that this insight will help improve methods for the gentle cleaning of fruits and vegetables, potentially leading to a commercial food-cleaning device that they call a “fruit Jacuzzi.”

As bioengineer Sunghwan “Sunny” Jung of Cornell University points out, bubbles injected into fluid have long been used to clean biofilm-encrusted surfaces in settings such as wastewater treatment facilities. Experts generally believe that the technique works because bubbles flowing over a surface exert a shear force, parallel to the surface, which tends to remove attached contaminants. “It’s similar to how you move your hand along the surface of your skin when you’re cleaning your body, applying a shearing force at the surface,” says Jung. Even so, he says, little is known about the basic science behind the effect and in particular about how the motions of bubbles within the liquid might optimize the cleaning.

To clarify those details, Jung and colleagues undertook a series of experiments. They first coated each of a set of glass microscope slides with either a mixture of milk- and flour-based proteins or with a culture of the bacterium E. coli. These coverings, says Jung, mimic the kinds of contaminants found on real industrial surfaces and food products. The team then immersed each slide in a water tank, with the coated surface facing down, and used a syringe to release a stream of bubbles from below. The experimenters could adjust the angle of the slide relative to the horizontal. For each test, they subjected the slide to a six-minute stream of bubbles that slid upward along the angled surface.

After the cleaning, they measured the amount of the contaminating film that had been removed by estimating the transparency of each slide compared to its original uncontaminated condition. For both slide coatings, the experiments showed that significant cleaning took place at all angles tested. But the cleaning effectiveness increased gradually with angle from 5°, where the transparency was about 70% of that of a pristine slide, up to 20°, where it reached roughly 90%. The transparency then dropped for larger angles, falling to about 38% at 40°, the largest angle tested.

Jung and colleagues also ran numerical simulations, which accurately predicted the speeds of bubble flow along the slide. In addition, they found that the shear force on the slide rose to a maximum at an angle of 22.5° before rapidly decreasing at steeper angles.

To explain the existence of an optimal cleaning angle, the researchers point to the two main factors that influence the shear force that the bubbly layer of fluid can apply to the surface: the flow speed and the layer thickness. As the team observed in the simulations, increasing the slide’s inclination allows bubbles to rush along the surface faster. The higher speed increases the cleaning shear force. However, with increasing angle, the buoyant force on the bubbles—always directed vertically—has a decreasing component directed against the surface, which reduces the average time that bubbles spend pressed against it (and increases the layer’s thickness). The interplay of these two factors leads to a maximum force and optimal cleaning at about 22.5°.

Jung hopes to build on the results by designing new cleaning equipment for the food industry. He envisions a “fruit Jacuzzi” that could gently but effectively clean fruit using a bath of directed bubbles.

“This is a great example of how fundamental research in fluid mechanics can have immediate practical consequences,” says Roberto Zenit, an engineer and specialist in fluid mechanics at Brown University, Rhode Island. “This paper basically tells you how long your fruit would need to be ‘bubbled’ for a film of bacteria to be washed away.”

–Mark Buchanan

Mark Buchanan is a freelance science writer who splits his time between Abergavenny, UK, and Notre Dame de Courson, France.

References

- A. Hooshanginejad et al., “Effect of angle in removing proteins or bacteria on a tilted surface using air bubbles,” Phys. Rev. Fluids 8, 043602 (2023).