Squeezable Metal Offers a Greener Approach to Refrigeration

Refrigeration systems that use materials that cool in response to an applied electric, magnetic, or mechanical force offer environmentally friendly alternatives to the greenhouse-gas-leaking ones found in most homes and factories (see Feature: In Hot Pursuit of 21st Century Cooling). Now researchers have demonstrated a cost-effective, scalable version of one of these so-called “caloric cooling” systems [1]. Their approach, which uses a material that responds to a mechanical force, exceeds performance records set by methods that rely on magnetic fields. The researchers say their technology is also much less expensive to make and to operate and could be ready for commercial use within a year.

Magnetic-based cooling systems had an early brush with fame in 1998 with the demonstration of a near-room-temperature system that kept its contents cold for 1500 hours [2]. In that system, a magnetic field was applied to a magnetocaloric material, resulting in a temperature increase, as atomic vibrations compensated for the entropy lost as unpaired spins in the material aligned. Turning the field off reversed that increase, allowing the material to act as refrigerant that could be used in the cooling coils of a household fridge. But inducing the magnetocaloric effect requires strong (> 1 tesla) magnetic fields, which can only be provided by expensive permanent magnets that contain rare-earth alloys.

An alternative approach is to use an elastocaloric material. Such a material undergoes an entropy-induced temperature change when subjected to a mechanical force that is large enough to partially change the phase of the material. In 2012 Ichiro Takeuchi of the University of Maryland discovered that when stretched, a commercially available wire made from nickel and titanium (NiTi) undergoes such a change, with the temperature increase being large enough to be felt by hand. He later found that a temperature decrease occurs when compressing NiTi tubes and then used the effect in 2016 to develop an early electrocaloric cooling system. “We started making [low-power cooling] systems using NiTi tubes in compression mode about ten years ago,” Takeuchi says.

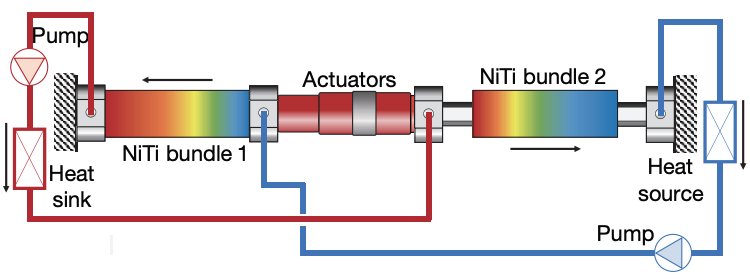

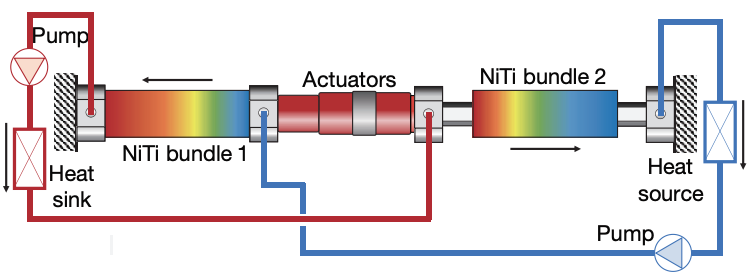

Now a team led by Takeuchi and Reinhard Radermacher at the University of Maryland has brought elastocaloric cooling to the front of the greenhouse-gas-free refrigeration race. Several engineering challenges stood between their 2016 demo and the new one, which has improved fluid recovery, reduced heat loss due to friction, and provided denser bundles of tubes. In the new device, water—the heat exchange fluid—flows through two bundles of commercially available NiTi tubes. The two bundles connect via an actuator, which applies a load to one bundle as it unloads the other, thereby creating cycles of compression that drive refrigeration. The system can operate in two different modes, depending on how much water flows through the system during a cycle. One mode optimizes the cooling power, the other the temperature span. The team demonstrated that they could cool the system by 22.5 K, compared to 4.7 K in their 2016 scheme.

Still, the team’s calculations indicate that the system’s overall efficiency could be improved by a factor of 6 by using more efficient actuators. Additionally, the researchers think that they could improve efficiency by switching the NiTi with a known copper-based material that exhibits a similar elastocaloric temperature change under a smaller stress. Such materials are currently not commercially available, but Takeuchi says that he is excited about implementing them in low-stress cooling systems.

The data from Takeuchi and his team “is very impressive,” says Kilian Bartholomé, who researches thermal energy convertors at the Fraunhofer Institute for Physical Measurement Techniques in Germany. He points out that almost all demonstrated elastocaloric systems use NiTi that was neither manufactured nor optimized for use in refrigeration devices, meaning that there is still “great potential” to increase the performance of the systems. Takeuchi believes that he and his colleagues will be able to improve the performance of their system enough to make the technology commercially viable within a year. The first application that he envisions: a compact wine cooler.

–Rachel Berkowitz

Rachel Berkowitz is a Corresponding Editor for Physics Magazine based in Vancouver, Canada.

References

- S. Qian et al., “High-performance multimode elastocaloric cooling system,” Science 380, 722 (2023).

- K. A. Gschneidner, Jr. and V. K. Pecharsky, “Magnetic refrigeration materials (invited),” J. Appl. Phys. 85, 5365 (1999).