A New Cathode for Rechargeable Magnesium Batteries

This article is part of a series of pieces on advances in sustainable battery technologies that Physics Magazine is publishing to celebrate Earth Week 2024. See also: Q&A: Electrochemists Wanted for Vocational Degrees; Research News: Lithium-Ion “Traffic Jam” Behind Reduced Battery Performance; Q&A: The Path to Making Batteries Green; News Feature: Sodium Batteries as a Greener Lithium Substitute.

Since the first prototype made its debut in 2000, rechargeable magnesium batteries have continued to be both technologically attractive and commercially out of reach. The attraction arises from magnesium’s advantages over lithium: it is 1000 times more abundant in Earth’s crust and is chemically less hazardous. The unrealized commercialization is largely down to the difficulty in identifying a material to serve as an effective and robust cathode. Tomoya Kawaguchi of Tohoku University in Japan and his collaborators may now have solved that problem through their demonstration of a material that satisfies one of the most important requirements of a good cathode: it can reversibly accept and release ions over repeated charging cycles [1].

The discharge of an electrochemical battery releases electrons that flow through the connected circuit. It also releases ions from the battery’s anode that flow through the battery’s electrolyte, in the opposite direction to the electrons, and then lodge in the cathode. The flows reverse directions during recharging. In a lithium-ion battery, the cathode is made from a lithium oxide and takes the form of either a layered material or a crystalline solid known as a spinel.

On paper, a magnesium oxide spinel should make a fine cathode for a rechargeable magnesium battery. However, in practice, the repeated insertion and release of magnesium ions into the cathode changes the cathode’s structure from a spinel to another cubic structure: a rock salt. A rock salt has a very densely packed structure that impedes the movement of magnesium ions, which are already sluggish because their double positive charge boosts their affinity with atoms in the lattice.

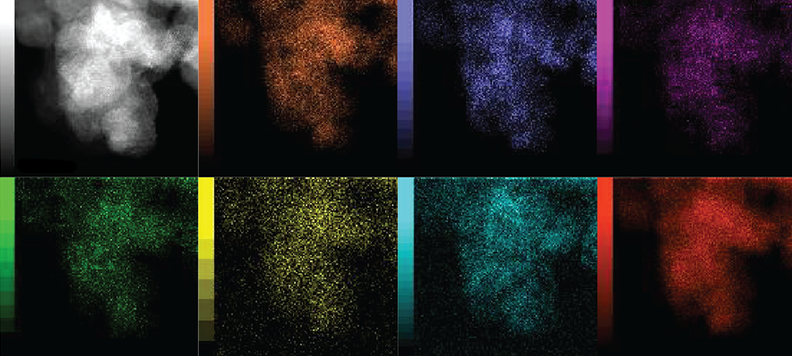

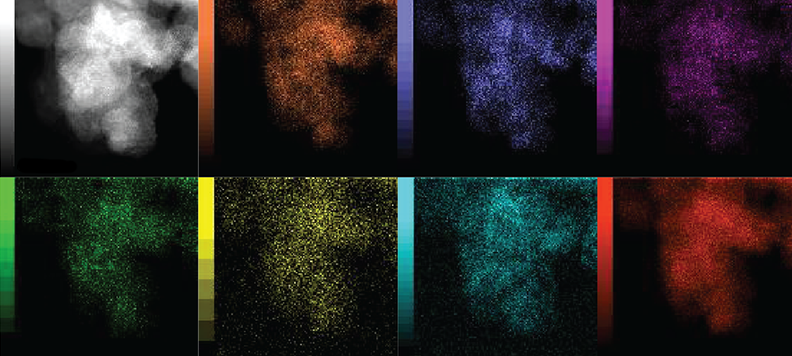

One solution to the mobility problem is to incorporate atoms, such as zinc, that can shore up the spinel structure. Unfortunately, that tactic only delays the structural transition. Kawaguchi and his collaborators decided instead to use rock-salt magnesium oxide but make its structure more open to flowing ions by including elements—chromium, manganese, iron, zinc, and molybdenum—whose atoms are larger than magnesium atoms. To make the material even more hospitable to the in-and-out passage of magnesium ions, they included a sixth element—lithium—which leaves the lattice during the first charging cycle, creating vacancies for magnesium ions. These vacancies remain open for subsequent charging cycles because only the magnesium ions have the right valence to fill them.

The new cathode material has the chemical formula Mg0.35Li0.3Cr0.1Mn0.05Fe0.05Zn0.05Mo0.1O (Kawaguchi calls the material M7O for short). The formula’s complexity reflects the material’s source of inspiration. In 2004, teams in Taiwan and the UK introduced the concept of a high-entropy alloy—a mixture of six or more metals in equal or near-equal proportions. Such mixtures form simple structures in which the atoms are randomly distributed (hence “high entropy”). The high-entropy approach was adopted for making novel ceramics, which attracted the attention of battery researchers because most ceramics and many cathodes are oxides. In 2021, Gerbrand Ceder of the University of California, Berkeley, and his collaborators used the approach to make a family of multielement oxide cathodes for lithium-ion batteries [2]. The family members had rock-salt structures.

Kawaguchi and his colleagues confirmed that M7O retains both its performance and its rock-salt structure over 34 charging cycles. However, for the cathode to perform at a useful current and voltage, the researchers had to heat it to 90 °C lest the magnesium ions move too slowly. Such a high temperature is problematic for batteries, as they could require a heater and a thermostat. Thanks to the high-entropy approach, there’s plenty of room for further improvements, says Kawaguchi.

–Charles Day

Charles Day is a Senior Editor for Physics Magazine.

References

- T. Kawaguchi et al., “Securing cation vacancies to enable reversible Mg insertion/extraction in rocksalt oxides,” J. Mater. Chem. A 12, 9088 (2024).

- Z. Lun et al., “Cation-disordered rocksalt-type high-entropy cathodes for Li-ion batteries,” Nat. Mater. 20, 214 (2020).