Spider-Inspired Microphone Detects Tiny Gusts of Sound

Human ears detect sound by sensing pressure fluctuations in the air when a sound wave passes by. Since the days of Alexander Graham Bell, engineers have designed microphones according to similar principles, using pressure-sensing diaphragms. Ronald Miles, an engineer at Binghamton University in New York, now has another way. Inspired by spiders that use the vibrations of their silky webs to sense sound, he’s designed a new type of acoustic microphone that detects the tiny gusts (viscous airflows) that sound waves create. The device, presented earlier this month at the 186th meeting of the Acoustical Society of America in Ottawa, Canada, is not yet as sensitive as pressure-based microphones, but the airflow-sensitive design could offer a way to improve the signal in small chip-based microphones.

Modern-day studio-grade microphones can detect the proverbial pin drop. Unfortunately, they’re also sensitive to thermal noise—random movements of air molecules that cause the pressure-sensing diaphragm to vibrate. This noise problem is especially acute for small, silicon-based microphones used in laptops, phones, and household smart devices. “You pay a penalty in noise when you reduce the sensing area,” says Miles.

Motivated by the goal of improving miniature microphones, Miles looked to the animal kingdom for alternatives to the pressure-responsive eardrums found in mammals and other animals. In previous work, he and his colleagues studied how some insects, such as mosquitos and fruit flies, sense sounds with hairs on their body [1] and how spiders react to sound via vibrations in their silk webs [2].

Both hairs and web threads are too thin to be affected by pressure changes from extremely faint sound waves; they are instead sensitive to sound-induced air flows. To confirm this, Miles devised a theoretical model for the air movement associated with sound waves and calculated its effect on a spider thread. The sound-driven air flow is an oscillation of air molecules in the forward–backward direction defined by the sound-wave direction. As the air flows past the thread, it exerts viscous forces, like the drag on an airplane wing. The calculations showed that a silk thread will move back and forth at the same velocity as the air for sound waves from 1 to 50 kHz—a very broad frequency range. “These spider silk studies showed that velocity of the air is a great way to sense sound,” he says.

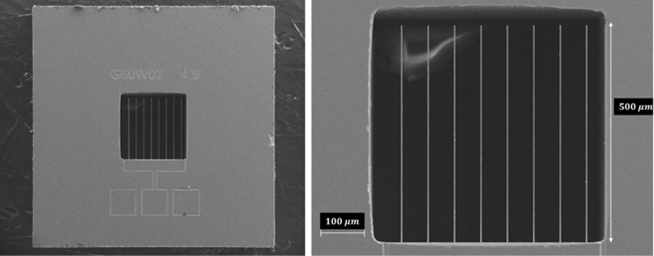

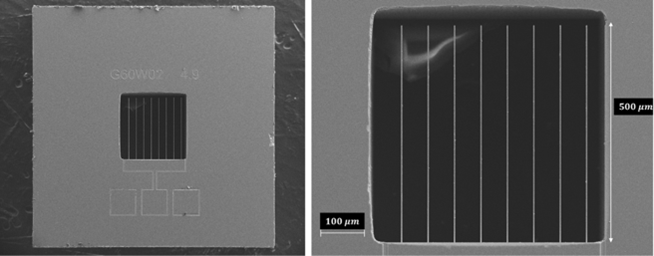

Leveraging their understanding of “spidey senses,” Miles and his colleagues have now built a flow-sensing microphone. As thin threads are not easy to work with, the team started with more manageable structures: microscale cantilever beams [3]. The researchers fabricated 0.5-µm-thick silicon nitride microbeams with a variety of lengths and widths and laid them over a central hole on a silicon chip. The team placed this microbeam array in an echo-free chamber that damps out all sounds and vibrations above 80 Hz.

Using laser motion-tracking techniques, they first measured the microbeams’ displacement in response to thermal noise alone. Then, they measured the microbeams’ displacement in response to pure sound waves from 100 to 1000 Hz. For each beam, the observed velocity directly matched that of the sound wave—irrespective of how long or wide the beam was. “We ultimately found that if you design a microphone to sense flow, instead of pressure, you can make it small without sacrificing performance,” says Miles.

To explain the success, Miles points out that sound-induced air flows occur over very small distances and small velocities. “Large objects like telephone poles are not affected by the viscosity of these small-scale flows,” Miles says. “But fine-scale things, like dust floating in the air, are,” he says. In terms of fluid dynamics, small objects have a very small Reynolds number, implying that viscous forces dominate other fluid-based forces, such as the random thermal forces that cause noise in pressure-based microphones.

The microbeam-based device responds to sound waves, but it is only a proof of concept. The researchers say that future designs could convert the microbeam motion into an electronic signal and that such a fully working microphone would likely have a sensitivity of 50–60 dBA, where dBA is a human-hearing weighted loudness measure (a pin drop on this scale is about 10 dBA). By contrast, good studio-type microphones can measure sound levels down to 0 dBA without experiencing a lot of noise; chip-based ones can get down to 20–30 dBA. But pressure microphones have had 150 years of development, “so give us a break,” says Miles. “Detecting air flow as a way to sense sound has largely been ignored by researchers, but the principles show that it’s worth considering.”

Federico Bosia, a materials scientist who specializes in bioinspired metamaterials at the Polytechnic University of Turin in Italy, sees promise in departing from the standard pressure-sensing microphone design and that the new approach offers many possible applications. He imagines other bioinspired designs might be developed for microphones “given the vast occurrence of hair-like flow-sensing elements found in nature.”

–Rachel Berkowitz

Rachel Berkowitz is a Corresponding Editor for Physics Magazine based in Vancouver, Canada.

References

- G. Menda et al., “The long and short of hearing in the mosquito Aedes aegypti,” Curr. Biol. 29, 709 (2019).

- J. Zhou et al., “Outsourced hearing in an orb-weaving spider that uses its web as an auditory sensor,” Proc. Natl. Acad. Sci. U.S.A. 119 (2022).

- J. Lai et al., “Effect of size on the thermal noise and acoustic response of viscous-driven microbeams,” J. Acoust. Soc. Am. 155, 2561 (2024).