Crumpling Coke Cans

Dent an aluminum can and it will be easier to crush from top to bottom. But predicting the exact force needed to crumple a dented can is notoriously difficult, requiring knowledge of the exact dimensions and position of the flaw. Researchers have now taken a step toward solving this problem, with experiments that relate the size of the dent to the axial force needed to buckle the can. Knowing this correlation could make it easier to predict when thin-walled, metal cylinders will crumple, informing the design of objects from beer cans to space rockets.

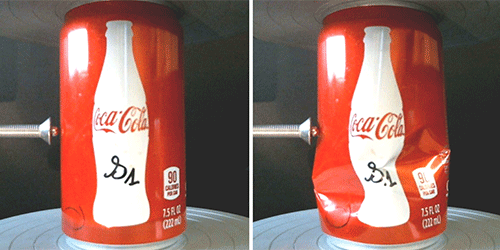

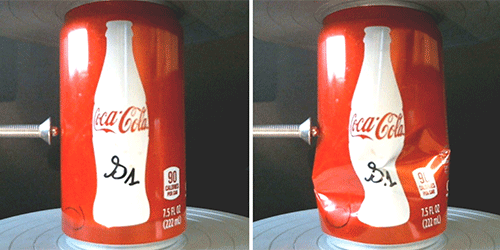

Emmanuel Virot, from Harvard University, and colleagues clamped an undented, empty Coke can between two metal plates to produce a force along its vertical axis. They then poked the side of the can using a metal ball attached to the end of a rod, continuously pushing the ball further into the can until it buckled with a loud snap.

Repeating this measurement with various axial-force strengths and ball sizes, the team mapped the conditions needed for buckling to occur. This map defines the can’s “stability landscape,” whose features indicate which combinations of parameters result in a crushed can and which don’t. For example, a can never buckles if the axial load is below a certain value, regardless of how big the dent is. But beyond a threshold axial load, all cans buckle once the dent is sufficiently deep. Because this sudden-onset effect is indicative of a general behavior known as a nonlinear instability, the team suggests that all dented can-shaped objects have a similar stability landscape. If this universality holds, then researchers might be able to use the stability maps to predict the strength of a space rocket or another similar object just by gauging its response to a gentle poke from the side.

This research is published in Physical Review Letters.

–Katherine Wright

Katherine Wright is a Contributing Editor for Physics.