Beam Splitter is Printed On-Demand

Once the stuff of science-fiction movies, 3D printing is today used to make machine parts, novelty toys, and even artistic sculptures. The technique is now finding its way into physics labs too. Faced with needing a specialized part for an experiment with molecular beams, Andreas Osterwalder and Sean Gordon of the Swiss Federal Institute of Technology in Lausanne (EPFL) showed that printing the component can be a better option than machining it.

The team wanted a device that would split a beam of polar neutral molecules in two, without affecting the molecules’ speed or rotational state, and without touching them. Their approach entails sending the beam through a Y-shaped channel in which the molecules are confined to the channel axis by electric fields with a hexagonal or clover-shaped cross section. Such fields can be generated by thin, voltage-carrying metal rods that are arranged in either a hexagon or a square. But the rods have to be carefully machined and polished and then positioned with high precision.

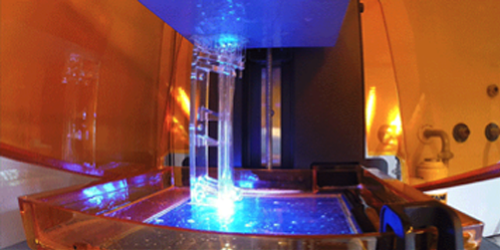

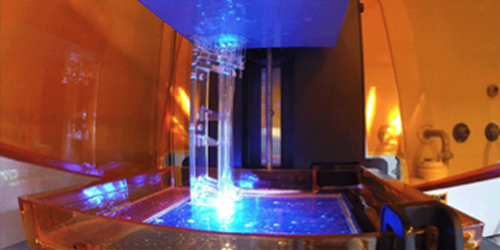

Osterwalder and Gordon instead opted to print the whole splitter in their lab with stereolithography, in which a laser forms each layer of the object by polymerizing a liquid resin. The group then sent the piece to a company that used electroplating to coat sections of it with nickel.

In tests, the printed beam splitter worked as designed. And compared with machined and mechanically polished devices, its metal surface had fewer scratches. Such scratches can cause damaging electric-field arcs between the rods. Another benefit of printing is speed. Machining the same part would take months, but printing and electroplating took under three days. In fact, the team says, the longest wait was for the shipping.

This research is published in Physical Review Applied.

–Jessica Thomas

Jessica Thomas is the Editor of Physics.